Not sure if we’re in peak season right now?

International freight is not always smooth sailing. A few times a year, it goes through a particular patch of rocky waters, better known as peak season.

There are two main peak seasons in the shipping year – the holiday retail peak season bump that essentially lasts from mid-August through mid-October and a shorter second peak season, spurred by the Chinese New Year in January/ February.

During these times demand is high, supply is low, prices go up, and container capacity can become scarce, leading importers with concerns about their ability to actually make their supply chain work.

Here are some tips to ensure that it can.

When is Peak Season?

The main indication that we’re in peak season is usually a spike in freight prices.

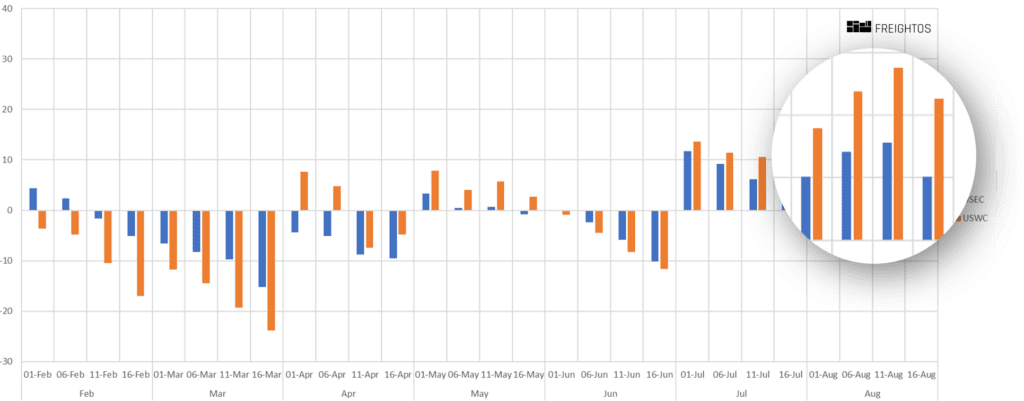

As you can see in the below snapshot of 40′ container rates from China in 2017, carriers try to push through price hikes throughout the year, but they usually taper off by later in the month. In fact, April 2017 saw shipping prices increase by 7.6% before dropping to 4.8% only days later, and then actually falling below the previous month’s prices by April 10. May’s General Rate Increase (GRI) bumped prices up 7.8% but dropped to just a 2.7% increase by the end of the month. Even July, which many sources claimed was the start of peak season, didn’t hold it’s GRI for long – a 13.7% GRI was ultimately reduced to just 4.9% by the middle of the month.

But data from August made it clear that peak season had arrived. For the first time in 2017, the price of shipping continuously increased as the month progressed.

Source: Freightos International Freight Index

What Causes Shipping Peak Season?

According to Econ 101, the main reason is demand.

Starting with back to school, through Black Friday and Cyber Monday, and down to those last-minute holiday sales, The last few months of the year are prime shopping season – and everyone wants their goods on the shelves when the shoppers come running.

In fact, for some retailers, the holiday season can represent as much as 30% of annual sales.

It doesn’t help that a Chinese National Holiday called Golden Week starts on October 1st and lasts for 7 days. That means that factories and suppliers are closed for a full week smack in the middle of busy season. Thanksgiving weekend sales depend on getting orders in before Golden Week, making the window for shipping in time for the holidays even smaller.

With so much demand, carriers know that they can raise prices, and people will still be fighting for supply. During peak season, expect to pay a peak season surcharge. Carriers already charge higher base rates in the peak season, so this supplemental charge seems unreasonable. But you have little choice but to pay.

So how can you beat peak season prices?

1. Prioritize Your Peak Freight Shipments

Not all shipments are created equally, and if you have specific products that need to get in on time, maybe something with a bit more demand than your other wares, those need to come first.

During peak season, shipments can and can get held up. If a ship is at overcapacity, a container can easily get rolled (an industry term that is essentially the same as a flight being overbooked).

So first of all, you should tell your freight forwarder which boxes or containers contain the higher priority goods. Forwarders will get some notice before a shipment is rolled and they can help ensure that higher-priority boxes or containers are protected.

Also, approach peak shipping season with a clear forecast of what your peak retail season will look like. Use data from previous years to forecast sales and couple that with industry trends. This will help dictate what and how much you import.

You can also prioritize by delaying the customization of your goods. Let’s say you sell purses, and customize those purses with different embellishments that are shipped separately. The embellishments are important, but they can wait until closer to the sell date. The purses are the key product, and shouldn’t be rolled if it can be helped.

Last, try to narrow down what you’re shipping by focusing on the essentials. Instead of bringing in dozens of options for your product with unproven selling power, focus on your core business and core brands to ensure that you are not left with an abundance of containers that might delay your shipment and still be left unsold.

2. Split Shipments

An important mantra to keep in mind throughout peak season is to ship what you can when you can.

There are a few ways you can do this.

If you’re shipping multiple containers in one shipment, you might want to separate them on multiple bills of lading. Carriers roll containers according to the bill of lading – not the container. So if you have 5 containers on one bill of lading, and your bill is rolled, then all of the containers get rolled. But if you separate them into multiple bills, you might still be able to get some containers through.

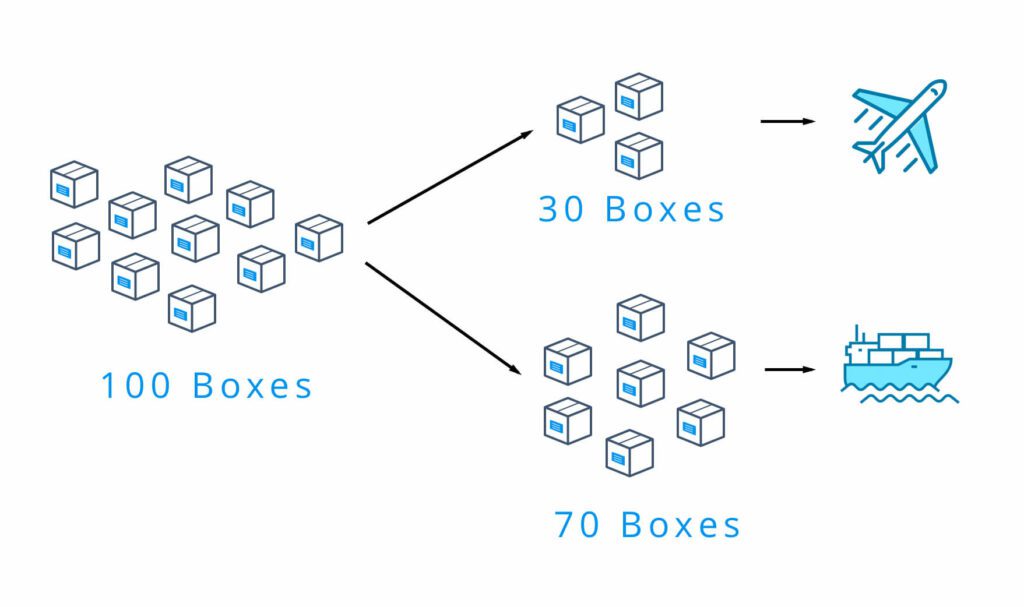

If you’re shipping LCL, you should stagger the shipment to make sure you at least have some stock at your disposal, regardless of potential delays. So for a 100-box shipment, you might put 30 on a plane to get them within the week and ship the other via LCL. Yes, air freight costs more, and yes shipping twice is more of a hassle – two invoices, two packing lists, two handling charges, etc. But consider it safety stock – that inventory can last you through any potential ocean delays.

One thing you want to avoid? Trans-shipments.

Some carriers rely on transshipments – or indirect shipments. A carrier might depart from Shenzhen and stop in Singapore or Korea for any number of reasons from customs to consolidation. Some of those shipments can save money, however, they face the risk of being rolled twice – once at the first leg, and then again on the second leg. During peak season, this is incredibly likely, and frankly, not worth it. So try to find a direct service before accepting a transshipment.

3. Slower Shipments, Faster Delivery

Everyone is rushing to get their goods overseas as quickly as possible. This means that lots of people are clamoring for those shipments with the shortest transit times…leaving shipments with slightly longer transit times prime for the taking.

If you’re able to plan ahead, sailings with slower transit times are less likely to roll your cargo because they’re less popular. Often it’s only a difference of a few days on the sailing schedule – a 15-day transit time vs. a 20-day transit time. If your shipment gets rolled on a 15-day transit time, it can get held up for up to 7 days – which means it will actually arrive after the later transit time.

Anyway, a longer transit time basically just means that you’re getting free warehousing on the ocean for an extra few days.

Think about your transit times in terms of speed to need.

If you ship early enough and know you have some wiggle room, it might be better to pick the slower time. If your shipment is really that time-sensitive that it can’t wait a few days, then you’re probably better off shipping air.

Also, if you break out a quarter of your goods as suggested to ship via air earlier, then your need is certainly lessened for that ocean shipment as you have inventory on the shelf, and so it will likely be worth waiting those extra few ocean days.

Last, you should understand shipping schedules to make sure you’re not rushing and paying your factory extra for an earlier delivery that’s not actually earlier. Usually, the consolidation of LCL shipments into containers only happens once or twice a week, let’s say every Thursday. So your factory might tell you there’s a batch of inventory ready on a Friday, and then another batch on a Wednesday.

You might think you can get them both booked via ocean and have one set of goods arrive 5 days before the second. But more likely, the first set of goods will wait in a warehouse for the Thursday departure, only to be joined later in the week by the second set of inventory, also booked on the same boat.

Sometimes waiting is okay – and will ultimately save you time and money.

4. Safer Shipments: Insurance Up

We’ve talked extensively about the importance of securing cargo insurance for any shipment, but this is particularly relevant during peak season.

Ship happens.

And if it does, if your goods never arrive or are damaged during transportation, you could be at a serious loss, since ocean and air carriers only provide a basic, insufficient level of insurance.

The premium for comprehensive cargo insurance (a mere 60 cents for each $100 of insured value) is not a material cost. And you should only accept comprehensive cargo insurance. It will keep you covered and is worth the outlay.

With more ships and more cargo, there’s simply a greater risk of something going wrong. For example, cargo theft tends to surge during peak season. This is especially true of LCL shipments, as they go through many more hands than containers when you consider the consolidation, deconsolidation, and the different sheds. Plus boxes are more visible, which makes them more susceptible to pilferage.

Protect yourself from the get-go.

5. Stick with Trusted Forwarders

Through all the decisions you’re making about your peak season shipments – what days to choose, how to prioritize your shipments, even how to acquire insurance – you need a partner you can trust.

Many forwarders book contracts with different carriers, and then pull out last minute when they find a better price. In fact, 25% of ocean bookings are canceled in this pattern. Carriers don’t love that, and if they see that forwarders have canceled a lot of bookings with them, they won’t allow them space.

So you want forwarders you can trust, and you also want to open yourself up to different forwarders, depending on how many shipments you have. Diversifying your provider options opens you up to a mix of carrier contracts, different transit time options, and different service levels.

But ultimately, you want a partner who knows their stuff. Choose wisely and you won’t regret it.

To summarize, during peak shipping seasons, prioritize high-demand shipments and collaborate closely with your freight forwarder to prevent delays. Employ strategies like splitting shipments into multiple bills of lading, combining air and sea freight for safety stock, and opting for slower shipping options to reduce transit issues. Additionally, invest in comprehensive cargo insurance to safeguard against potential losses. Build relationships with trusted forwarders who maintain stable carrier contracts and offer diverse service levels to ensure efficient and timely deliveries.

Check out our recent post on Peak Season Tips from Experts, for all the most recent peak season updates!